KӦHLER Anode / Cathode Cell

KӦHLER supplies both Tubular wrapped and Extruded type Anode/Cathode cells .

Each with unique specificity ,maintenance and cost-efficiency.

Since Anode/Cathode cells must be manufactured individually for customers, Our engineering departments will provide you the best advices , design specification and options meet your requirements proudly for free.

A. KӦHLER TUBULAR ANODE/CATHODE CELL

KӦHLER tubular Anode/Cathode cell can be used in E-COAT painting systems with most types of paints. It serves as the opposing electrode and simultaneously removes solvent (usually a common organic acid) from the paint to maintain chemical balance. We use American outstanding quality ion exchange membrane with low resistance, high perm-selectivity.

-

APPLICATION

-

E-coat process in automobile, home appliances

and other industries

-

ADVANTAGES

-

American outstanding quality ion exchange membrane

-

Available in various cell type of open, union, flange, bare, etc.

-

Available in various material of electrode

(SS 316L / Ti, Titanium with iridium coated.)

-

Low resistance, save energy

-

Simple and economic module replacement.

-

Integrated high strength supported core tube with high porosity.

-

Cell types Features:

There four features types of Anode/Cathode cells available for different propose as followed:

-

Open type : simple design with high cost performance

-

Union type : resistance to heavy pressure, high cycle efficiency, simple installation

-

Flange type : corrosion resistance, high cycle efficiency, can be used at bottom of paint tank

-

Bare type : resistance to heavy pressure with seamless Titanium with iridium coated electrode, corrosion resistance

-

SPECIFICATION

AMI-7001S/AMI-7001CR ANION EXCHANGE

FLAT SHEET MEMBRANE Feasibility ;Model:AE3

.jpeg)

B. KӦHLER EXTRUDED-type

KӦHLER Extruded-type membrane is more energy-efficient with respect to all the flat membranes, and the EX-type is self-supporting extruded membrane does not need an anode made of grids nor external or internal support. It does not need a PVC grid like a flat membrane does.

-

ADVANTAGES

-

KӦHLER EX-type membrane can expanded freely from the dry state to the wet state and offers:

-

Lower energy absorption

-

High penetrating power at a given voltage (15 to 20% or more)

-

Process safety

-

The EX anodes allow pressurised anolyte circulation (650 L/h at 0.3 bar and up to 1000 L/h at 0.6 bar).

-

The calculated requirements of the EX anode go from 3 to 5 L / h / Ampere / m 2.

-

Zero losses and less paint caking thanks to the impermeable extruded membrane.

-

Because of its special construction, there is no risk of the EX cell overflowing in the bath.

-

There is no risk of syphoning if the EX membrane should break. Since the anolyte circulation is pressurised, it provides a counter-pressure that prevents this risk.

-

In the event of bacterial contamination, the EX anodes can be washed and completely emptied by means of a screw plug at the bottom.

-

EX-type expands as it has no external /internal constraints.

Maintenance

-

EX-type can be dried, just wash the surface with demineralised or tap water. Leaving the anolyte circulation at a lower flow rate during maintenance.

-

The surface of the ex membrane can be brushed with “scotch brite” to remove caked/dried paint.

-

EX anodes weigh only 15 kg each (the active membrane is 2.1 m long).

-

No special lifting equipment is required to move or replace KӦHLER EX-type anodes on their supports (one or two operators).

-

At most two people are required to carry out maintenance on an AUF anode.

-

KӦHLER EX-type anode can be extracted easily, thanks to a PVC screw at the top of the cell.

-

Lifetime

-

The EX membrane remains smooth without wrinkling or breaking that would clog the membrane with paint pigments.

-

KӦHLER gives twelve months warranty on the EX membrane (EX electrodes not included) for a continuous or discontinuous system.

-

Experience shows that EX anodes function properly even after 5 years.

-

Turning only the EX electrode by 90° every six months makes them last longer.

-

MEMBRANES SPECIFICATION

In electrophoretic painting (cataphoresis, anaphoresis), ultrafiltration membranes are used to recover drag-out paint and to manage the bath’s chemical and physical parameters. The membranes offered have been specially designed for this process.

-

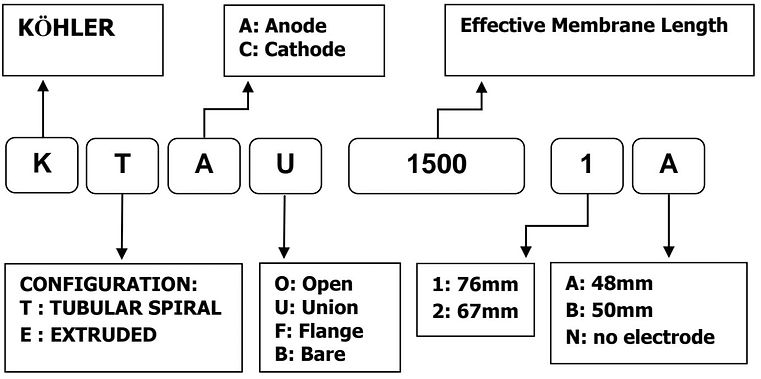

KӦHLER Anode /Cathode Order Coding:

-

According to the customer's request, the effective membrane length can reach to 6000 mm